Completing Precision Machined Parts with Wire EDM Services

Could your precision machined part benefit from wire EDM services?

At United Centerless Grinding & Thread Rolling, we provide a variety of finishing services for precision machine shops across the country, and our comprehensive capabilities include wire EDM.

Ideal for highly regulated medical, marine, and aerospace components, wire EDM (electrical discharge machining) cuts conductive metals using a precise yet pressure-free electrothermal process. The exceptionally thin wire can cut and contour parts to achieve extremely tight tolerances, mirror-like surface finishes, and tight corner radii.

Wire EDM easily cuts even the hardest materials with minimal waste production, making it incredibly cost-efficient for various projects. Here we’ve outlined a few of the ways our precision machining customers have leveraged our wire EDM services to complete their parts.

3 Examples of Completing a Machined Part with Wire EDM

1. Gear cutting and shaping

A customer had parts that required gear shaping, but the lead time for the custom tooling they needed was prohibitively long. We suggested wire EDM as a faster alternative for cutting the gear teeth. If you are in a jam, we can get you out!

Wire EDM enabled the customer to deliver precise parts to their end customer on time and with exceptional quality.

2. Creating exterior geometries

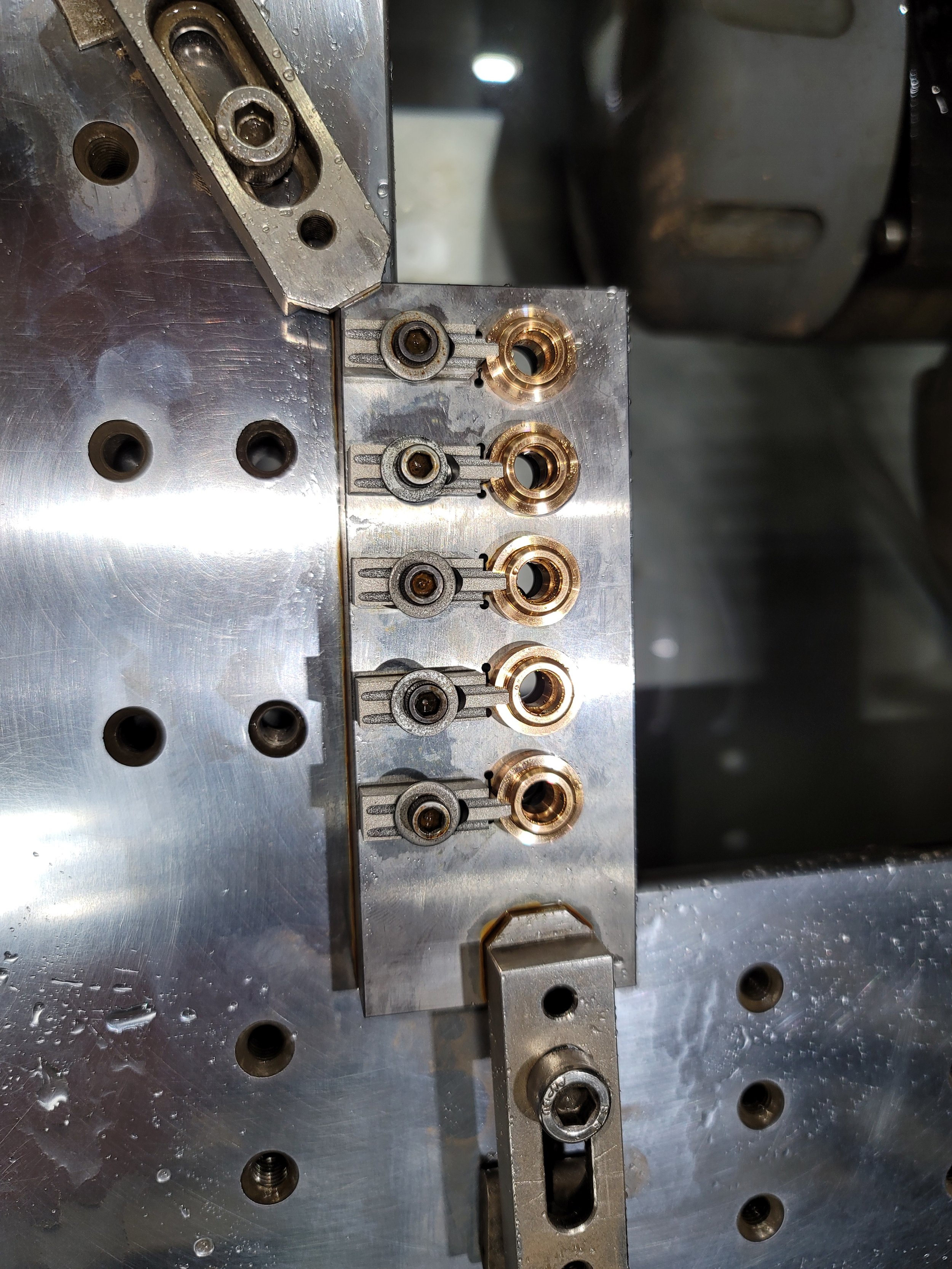

Wire EDM’s high degree of precision makes it perfect for cutting mating parts that demand proper fit and function.

United Centerless Grinding & Thread Rolling can use wire EDM services to cut the external geometries for parts that have already been milled on the inside. This approach is especially beneficial when a part’s exterior must orient precisely to its interior features.

When necessary, we use our engineering expertise to design the custom fixtures needed to hold parts in place for complex cutting operations. We can either give you the drawing to machine the workholding device yourself or build it for you right here in our shop to save time.

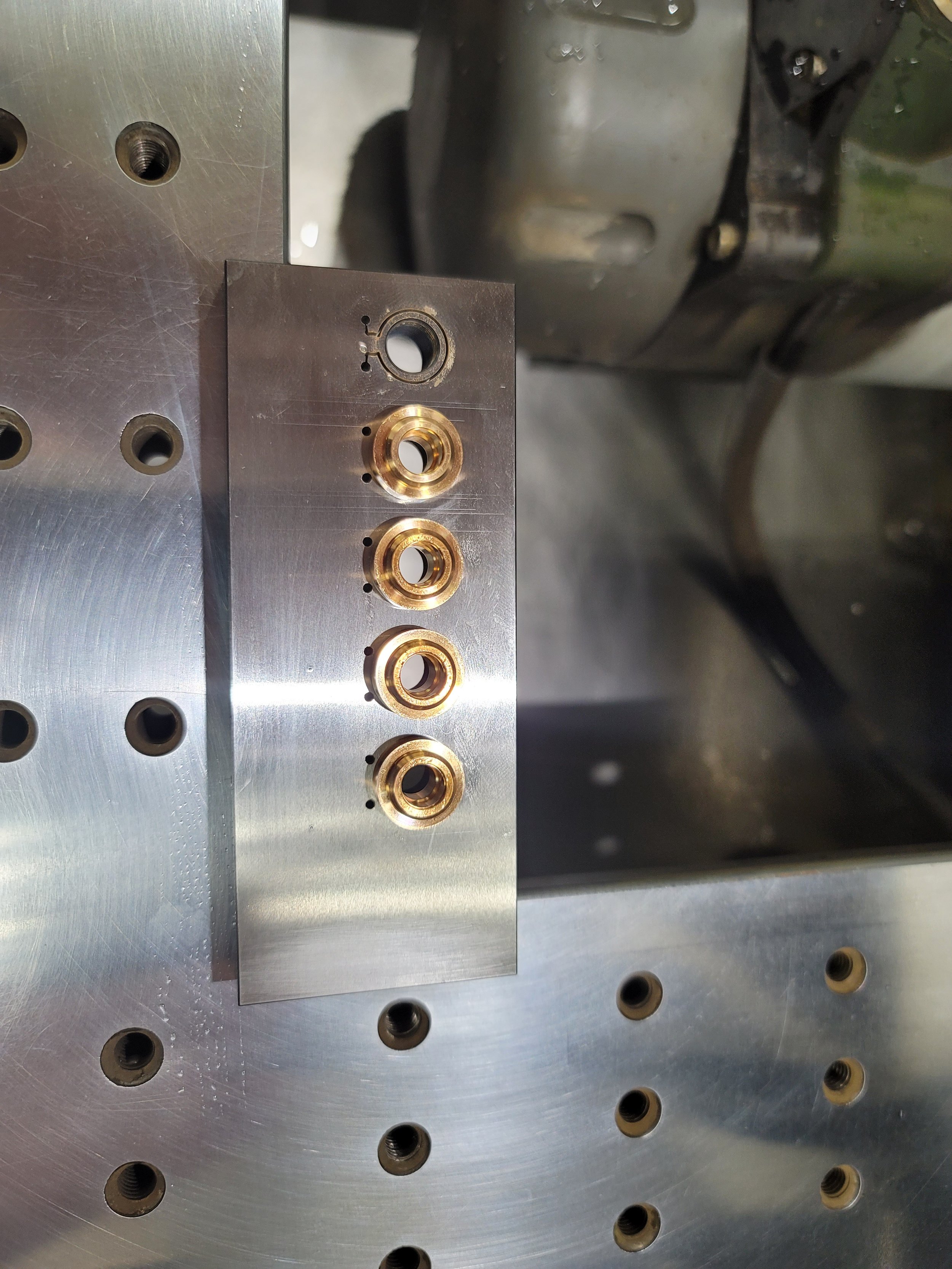

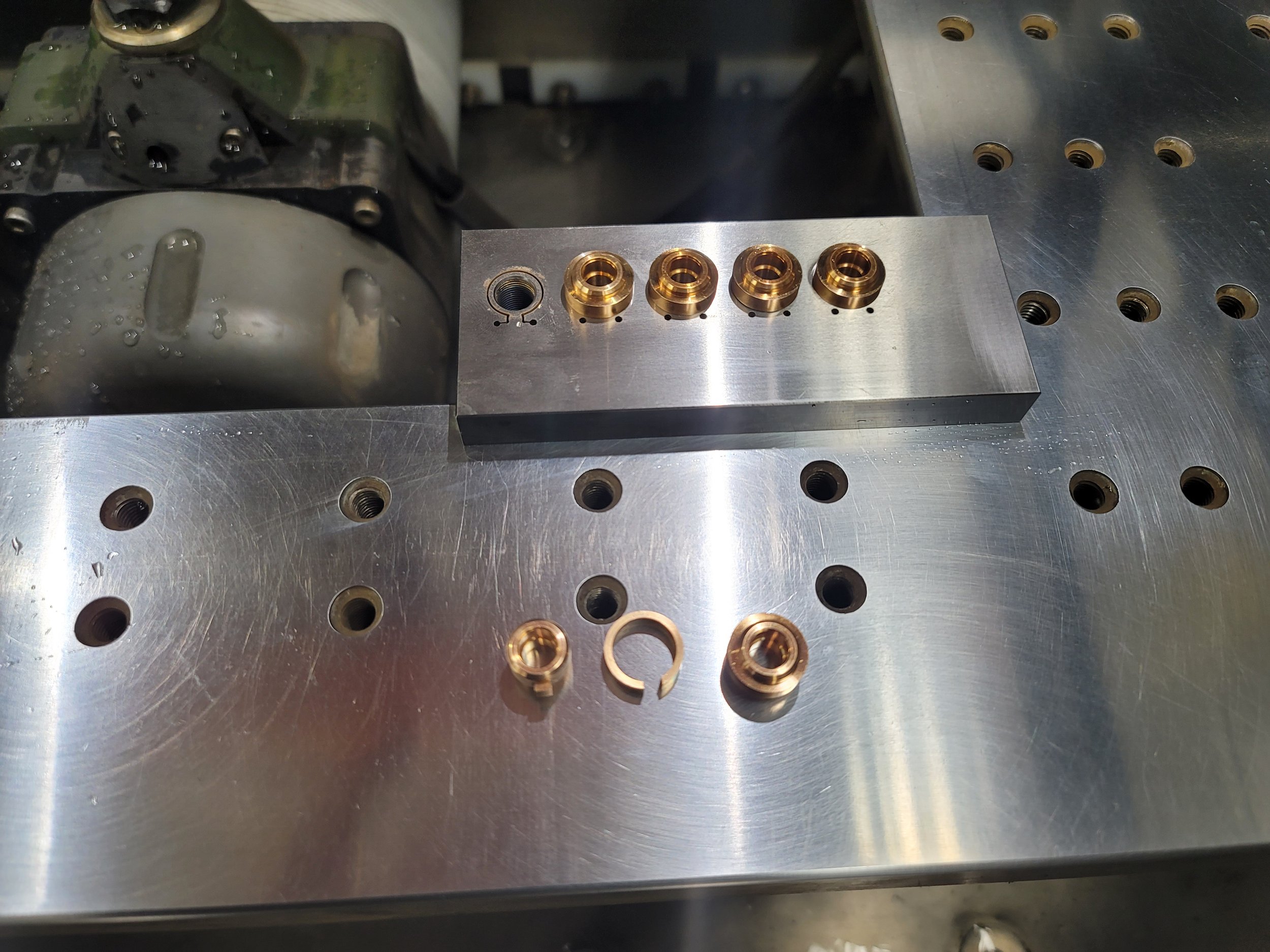

3. Cutting safety wire holes in nuts

We frequently perform hole popping operations for positioning safety wires in nuts using EDM drills. Our AgieCharmilles CNC EDM Drill 20 powerfully burns through-holes and blind-holes at diameters of 0.5 mm to 3.0 mm with accuracy up to one-thousandth of a millimeter.

We recently made a double-ended stud for an aerospace customer using this technique. With a thread on one end and a spherical radius/diameter on the other end, the middle of the part consisted of a hex with three safety holes.

We passed the part through three of our internal departments, first Swiss screw machining a partially machined 12-foot blank, next grinding and threading the part, and finally creating holes for safety wires with our EDM drill.

Whether you would like us to leverage our combined capabilities to make your part from start to finish or need wire EDM services to complete a part you already machined at your shop, we’re here to support you. Contact us today for a free estimate!