CNC Profile Grinding Services

Precision CNC Profile Grinding for Custom Carbide Tooling

Need top-quality custom crush roll, I.D. form, and other circular profile tooling without the long lead time? Consider us and get a quote.

When cylindrical parts call for a custom grinding tool, United CGTR uses CNC profile grinding to create carbide tooling tailored to a part’s precise dimensions. The custom tool enables impressively fast, incredibly accurate grinding for parts with intricate profiles or critical requirements for size, roundness, concentricity, and surface finish.

We’re proud to be one of the few centerless form grinding shops offering CNC profile grinding capabilities on in-house CNC form grinding equipment.

What Is Precision Profile Grinding?

Also referred to as form grinding, projection grinding, and copy grinding, profile grinding is a discontinuous grinding process that produces high-precision components and tools.

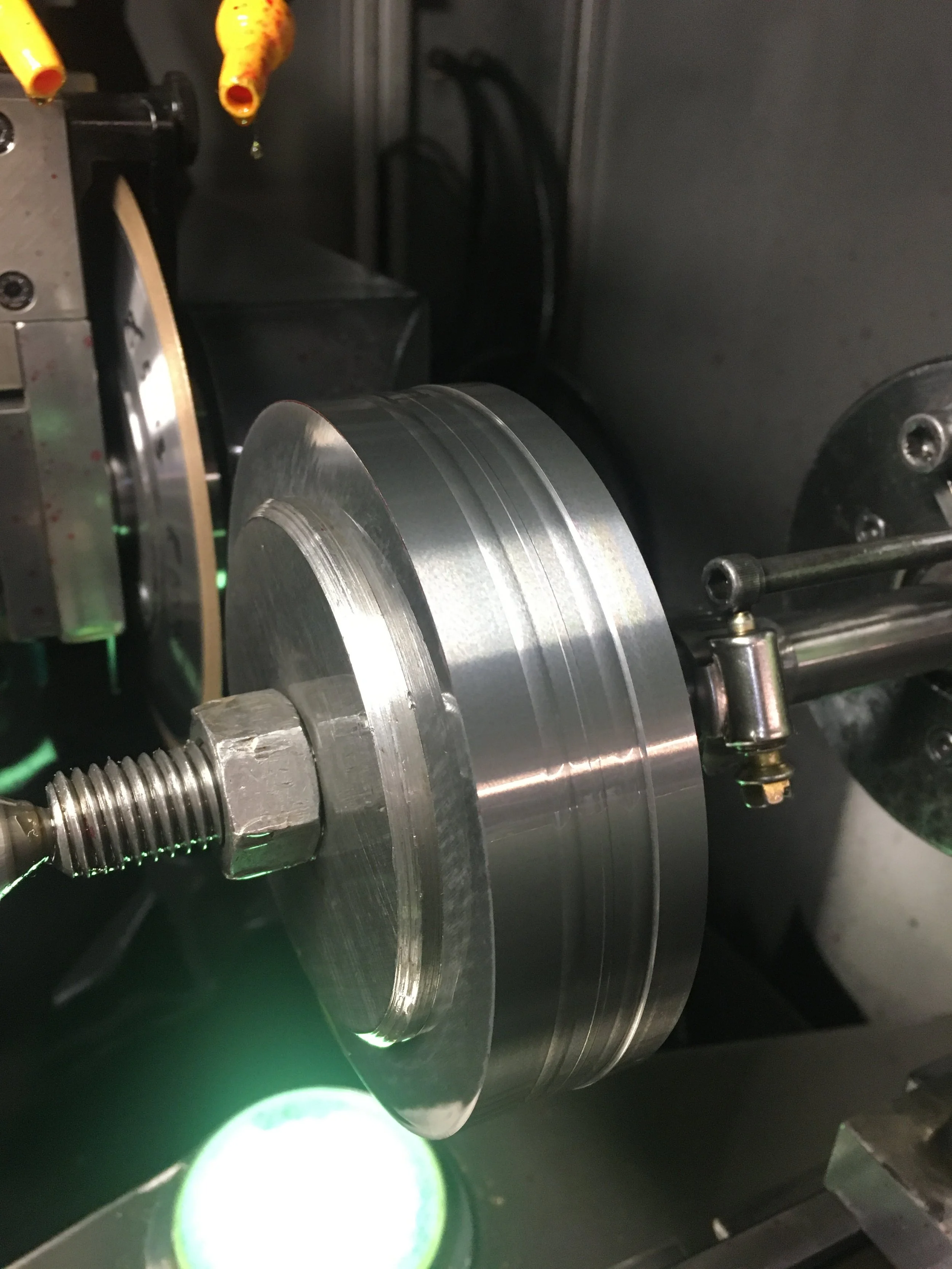

To prepare one of our CNC form grinding machines for profile grinding a tool, we first use a diamond dressing tool to shape the machine’s grinding wheel to the desired profile by straightening, surfacing, or forming the wheel.

Next, we grind the reverse profile of the final cylindrical part into the tool, enabling it to shape cylindrical parts with speed, accuracy, and precision.

Our Custom Tooling Capabilities

Every custom-made carbide tool we make can grind an average of 10,000 parts before it requires sharpening. We can sharpen the tools in-house in a matter of hours, eliminating outsourcing expenses and operational downtime.

Our custom tooling solutions include:

Crush roll tooling

I.D. form tooling

Other circular profile tooling

The custom tooling is used to make parts like these for aerospace, medical, armament, and other industries:

Our CNC Profile Grinding Equipment

Our Connecticut shop is one of only five US companies operating these powerful CNC centerless form grinding machines:

2002 Doebeli/Petewe CNC Form Grinding Machine

1998 Doebeli/Petewe CNC Form Grinding Machine

Unlike conventional form grinding equipment, our CNC form grinders hold a complete profile on a single grinding wheel, with left-to-right or right-to-left continuity. These exquisitely maintained CNC form grinders comprise granite surface foundations that prevent thermal expansion and enable unmatched precision.

Advantages of In-House CNC Profile Grinding

In addition to quality, speed, and cost-efficiency, our in-house CNC profile grinding services offer these key benefits:

Precision tolerances

When used to make crush roll, I.D. form, and other circular form tooling, our CNC profile grinding equipment can hold tolerances of +/-.00005”.

Small radii

Our Doebeli/Petewe CNC form grinding equipment is capable of achieving radii as small as 0.004”, and our Wasino CNC grinder can go down to 0.002”.

Superior surface finishes

We consistently deliver a surface roughness of 16 Ra right off our machines.

Shorter lead times

The lead time for custom crush roll, I.D. form, and other circular profile tooling is only 2-4 weeks—dramatically less than the typical 8-10 week lead time required for outsourced profile grinding services.

Get a Quote

As an AS9100D and ISO 9001:2015 registered shop, we monitor and measure quality throughout the grinding process to meet your critical specifications and quality documentation.

Use our simple contact form or call either—

860-289-2987

888-570-9496 toll-free