Centerless Grinding Services

Our Expert Centerless Grinding Services

How Does Centerless Grinding Work?

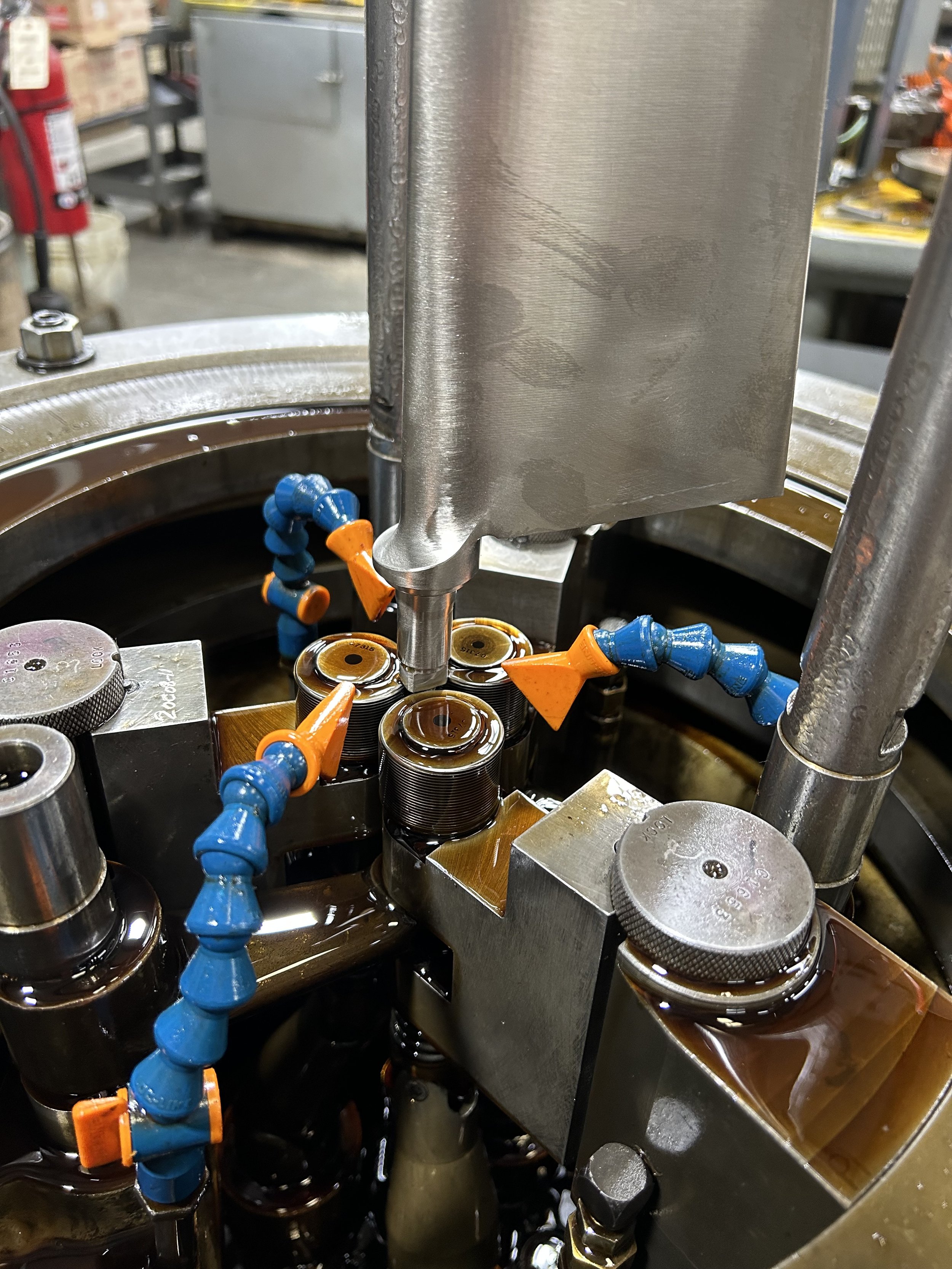

With the centerless grinding process, we place a tube or rod component on a work rest. Doing so positions the part between a regulating wheel that spins it in one direction and a grinding wheel spinning in the opposite.

Based on your specifications, we determine the distance between the wheels to grind an exacting outside diameter to achieve precision roundness, surface finish, and dimensional tolerance.

We use our centerless grinding machines to give you—

tolerances to ±.00005”

complex cylindrical, screw machined, formed, stepped, and conical shapes

multiple diameters

economical high-volume production runs

Infeed Grinding

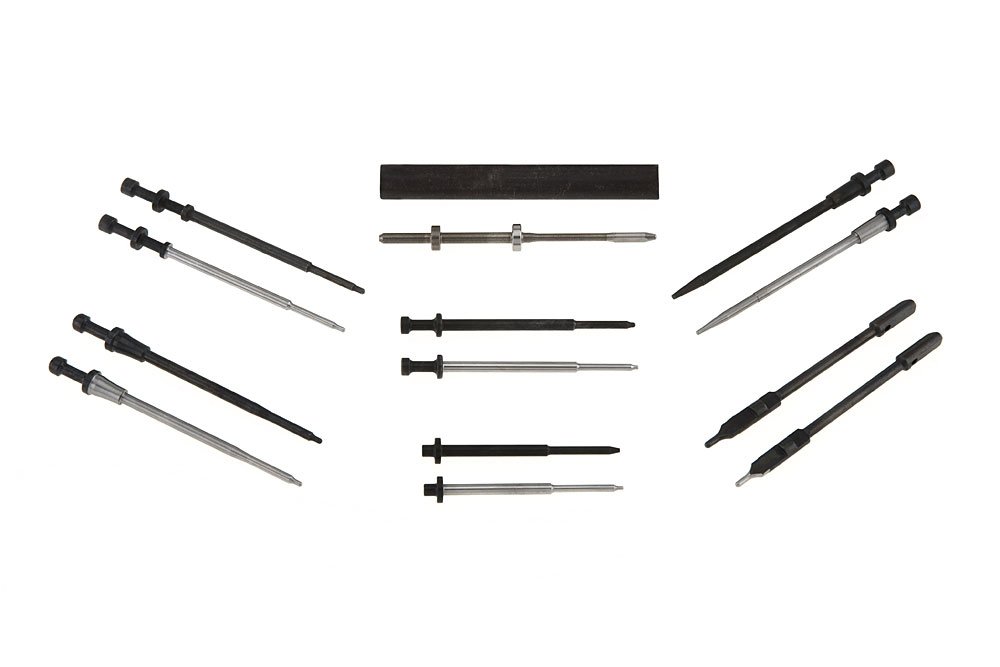

Our shop uses infeed grinding to grind tubular parts into intricate shapes with complex profiles, radii, various outside diameters, and tight tolerances.

We also refer to infeed grinding as plunge, profile, or end-feed centerless grinding. It’s one of the most effective methods to maintain a piece’s diametric profile. Examples of parts ground by infeed are bolts, studs, rivets, pins, and components requiring precise flats, slots, and notches. We use infeed to make industrial cutting tools, punches, and core pins for mold making.

Thru Feed Grinding

We use thru feed grinding for round simple shape parts that require consistent roundness across the length of the piece.

In thru feed grinding, the straight cylindrical workpiece goes in one side to pass between two wheels that grind all surface points of the bar. It exits the opposite side ground as a rounder straighter part to meet tolerance specifications.

Examples of parts shaped by thru feed are pins, dowel pins, and components requiring only the outermost diameter to be ground.

Form Grinding

Centerless form grinding uses a wheel with a cutting face contoured to the reverse shape of the final cylindrical part.

Examples of parts ground by form grinding are mandrels, stylets, pins, cutting tools, core pins, punches, and tubing.

Crush Grinding

Crush grinding forms a multiple shape part at one time. A firing pin is a great example. It’s a part well suited to crush grinding because it has multiple diameters, radii, and feature locations that can all be ground together.

Our Centerless Grinding Capabilities

Experience in grinding counts, because it’s a skill mastered from years of shaping ground components for more than 500 companies across the United States in aerospace, medical, armament, commercial, and automotive industries.

United Centerless Grinding & Thread Rolling began in 1960. We specialize in precision centerless, form, crush, and bar grinding services.

As an AS9100D and ISO9001:2015 registered shop, our quality assurance team monitors and measures tolerances throughout the grinding process to meet your critical specifications and quality documentation.

Our services include the following—

centerless infeed or end feed grinding

thru feed grinding

crush grinding

form grinding

NC form grinding

Our capabilities include—

wide variety of sizes and dimensions

– bar grinding lengths up to 30′

– 5.5″ diameter bar capacity (1,000 lb. max/bar)computer process planning

short and long-run productions

tolerances held to ± .00005

gage calibration system meets iso10012 standard

As an AS9100D and ISO9001:2015 registered shop, we monitor and measure quality throughout the grinding process to meet your critical specifications and quality documentation.

Get Your Quote

Use our simple contact form or call either—

860-289-2987

888-570-9496 toll-free

Are you looking for a centerless grinding shop to produce your complex aerospace, medical, or armament precision parts? Consider us and get a quote.

Why? Because you get more than 60 years of skill, experience, and know-how in precision centerless technology.

Our work for you begins where conventional machining ends. We are a centerless grinding company that makes small round diameter parts rounder.

What Is Centerless Grinding?

The term, centerless grinding, describes the process of removing material from a cylindrical part without using a spindle to turn it.

Centerless grinding produces a “machined surface” that a cutting tool in a turning process cannot deliver. With our grinding wheels, we remove material and finish the part’s surface with precision.

If you need straighter, rounder, and more precise-diameter pieces like the centerless ground parts below, consider us—

round bars

tubing

input shafts

pump shafts

bushings

pins