How to Prepare Blanks for Thread Rolling Services

Precision is paramount in high-risk industries like aerospace, and United CGTR takes that very seriously. When customers come to us for thread rolling services, we are committed to achieving the tight tolerances necessary for optimal performance, and that starts with using a properly prepared blank.

Best Practices for Preparing a Blank for Thread Rolling Services

First, here’s a helpful refresher on how thread rolling works. Unlike thread cutting, which involves removing material by physically cutting away at a workpiece, thread rolling is a cold forming process wherein a hardened steel die displaces the material to form it to given specifications. A rolled thread is notably stronger than a cut thread because it is never weakened by a cutting process.

That said, it’s critical to account for the material displacement that occurs during thread rolling when preparing the blank. Specifically, the blank’s diameter must be held to a highly precise tolerance of +/- 0.0002” to ensure that the final thread rolled component meets all specifications.

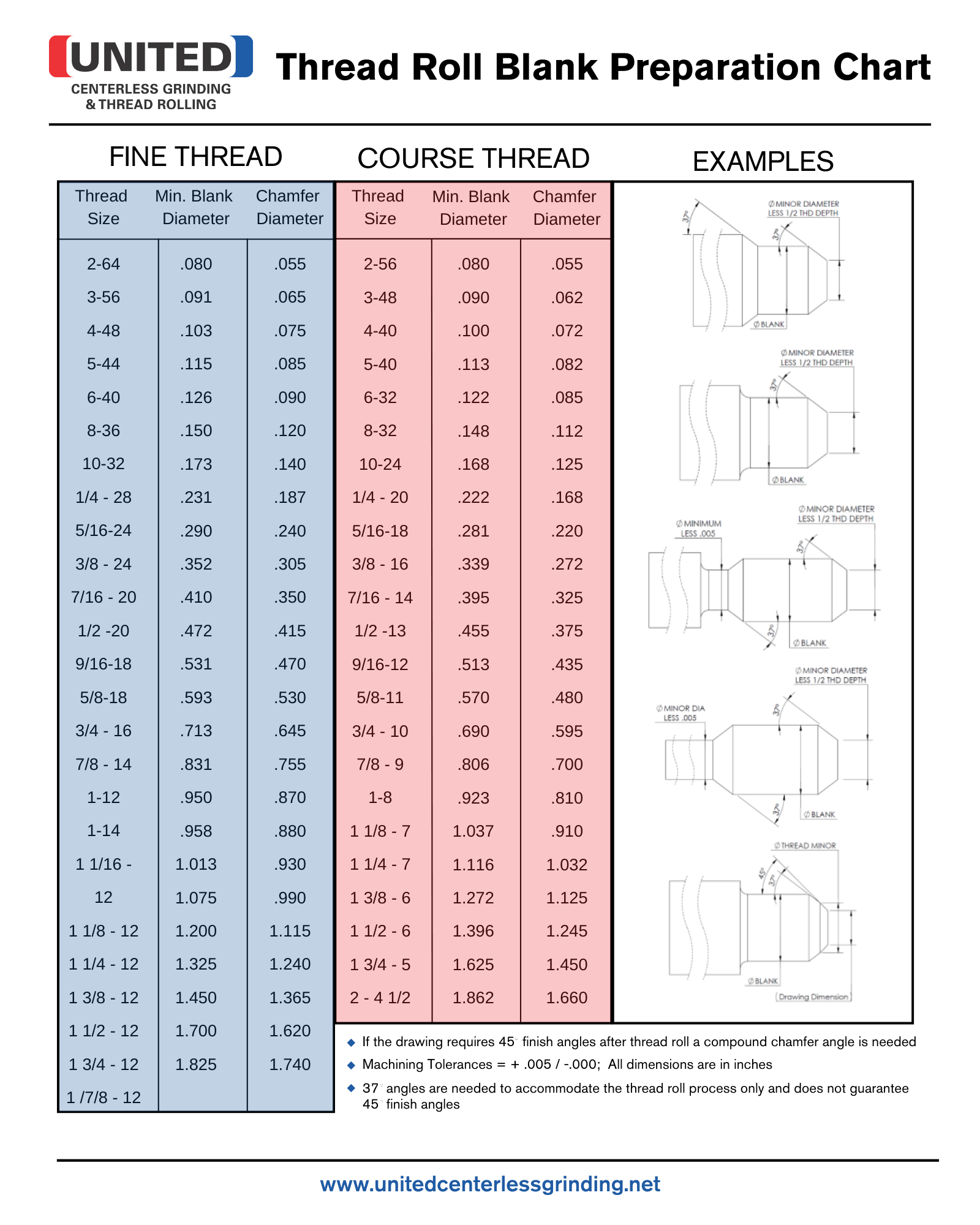

Download our Thread Roll Blank Preparation Chart here.

United CGTR’s recommended approach

For this reason, United CGTR strongly encourages customers to let us precision grind the blank in-house before performing thread rolling services. We ask that the blanks you provide have slightly oversized diameters held to tolerances of +/- 0.002” and approx. .005 higher than the high limit of the pitch diameter. We’ll then take care of grinding the blank to within a +/- 0.0002” tolerance so the material that is displaced during thread rolling is formed to its proper specifications.

“Can’t I just deliver the blank at the size you need it to be?”

Our Thread Roll Blank Preparation Chart

We understand that the idea of paying us for precision grinding services on top of thread rolling services can give cost-conscious customers pause. But here are a few additional factors to consider:

Efficiency. You might have a Swiss screw machine or lathe at your shop that can hold highly precise tolerances and wish to fully prepare the blank yourself. But think about what’s required: a machine operator monitoring the process closely. You may decide that’s not the best use of your internal resources, especially when we can achieve this step much more efficiently.

Rework potential. We can give customers a general idea of the necessary blank diameter, but how the material displaces can depend on various factors we may not know about until components are in front of us. For instance, the amount of wear on the die or even the specific threading machine we’re using can impact the outcome, increasing the potential for costly rework.

In short, many customers find that the cost of paying United CGTR to perform precision grinding services before thread rolling provides significant value in the long run.

Bonus Tip!

While on the subject of thread rolling services, here’s a bonus tip: Tell us how you’re inspecting your thread-rolled components. Are you using a Johnson Gage, Ring Gage or Single Pitch Micrometer? Where do you have your gages calibrated? How frequently? With this information, we can ensure our inspection approach aligns with yours.