Thread Rolling Services

Thread Rolling Makes Your Fasteners Stronger

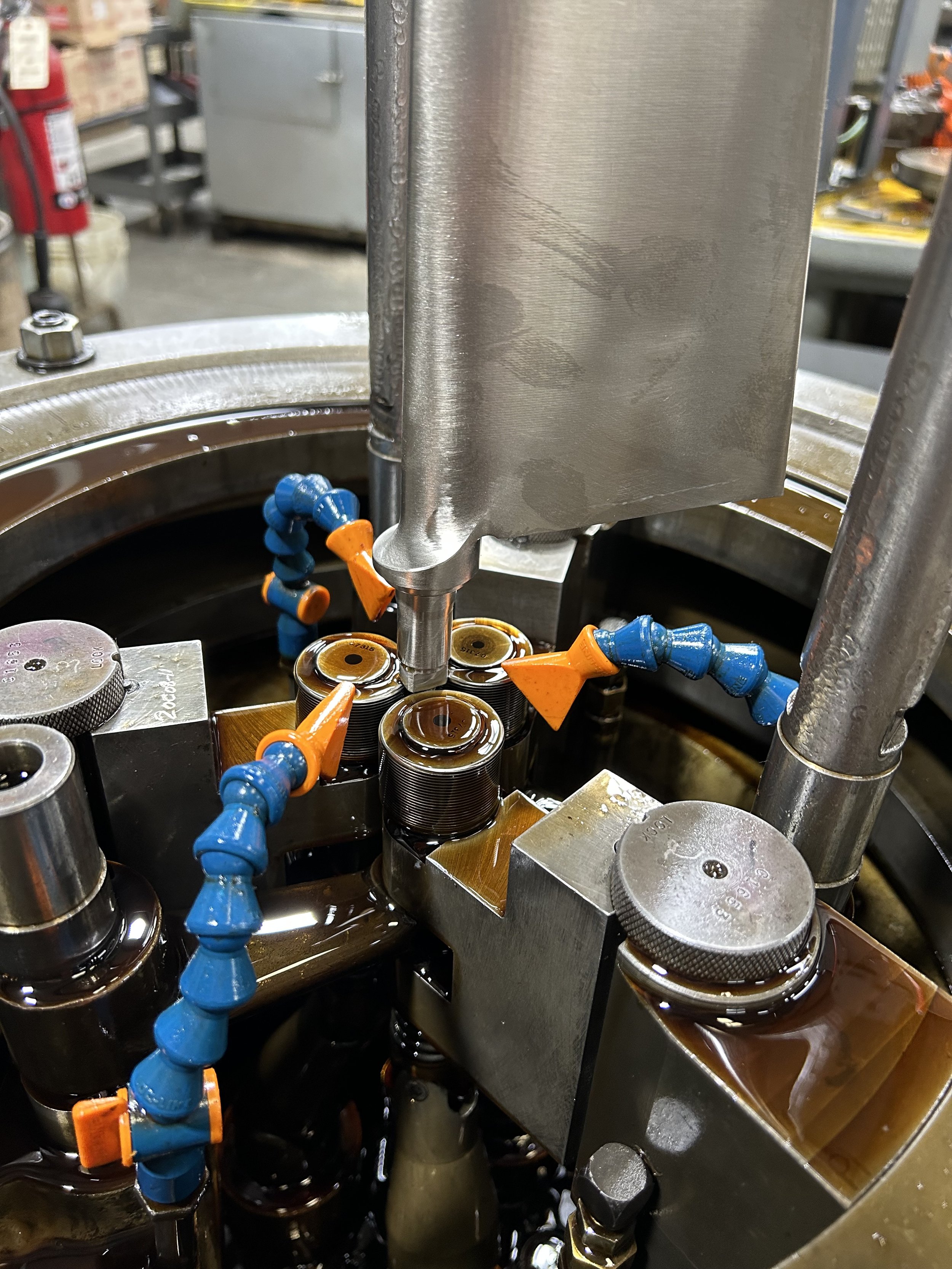

Our Thread Rolling Capabilities

We are United Centerless Grinding & Thread Rolling, serving more than 500 customers across the United States in aerospace, medical, armament, commercial, automotive, military, and marine industries. We specialize in both centerless grinding and thread rolling services.

Experience in the thread rolling process is essential to making your fastener strong and precise. That’s why we mastered the technology in 1960 and continue to specialize in aerospace thread rolling. Today our customers turn to us for thread rolling troubleshooting because of our extensive engineering experience in the industry.

As an AS9100D and ISO9001:2015 registered shop, our quality assurance team monitors and measures tolerances throughout the thread rolling process to meet your critical specifications and quality documentation.

As an AS9100D and ISO9001:2015 registered shop, we monitor and measure quality throughout the grinding process to meet your critical specifications and quality documentation.

Are you looking for a thread rolling shop to shape your precision threaded components with exceptional tensile, shear, and fatigue strength? Consider us and get a quote.

Why? Because you get more than 60 years of skill, experience, and know-how in delivering precision external rolled threads.

Thread Rolling Versus Thread Cutting

A rolled thread is stronger than a cut one because the process changes its physical properties by cold forging. The procedure supplants the part’s malleable material with hardened steel die formed to thread size and form.

Unlike the weakening effect of cutting threads that remove material, thread rolling moves molecules into the thread form, making it dense to improve quality and strength. Burnishing the steel dies produces a superior micro-finish that reduces wear and extends the life of your fastener.

We use thread rolling to form a range of components including—

fasteners

aerospace bolts

fittings

fluid connectors

nuts

setscrews

screws

tie rods

custom fasteners

Our services include—

precision thread rolling

standard pitches and metric

range size #0 (ott) to 1-1/8″

4″ length capacity

J form, metric, and left-hand threads

AS8879, AS7742, AS7452 thru AS7481 which requires destructive lab testing

knurling

Our capabilities include—

wide range of sizes and dimensions

computer process planning

stainless steels, nickel alloys, carbon steels, and titanium along with other space-age metals

We form your component based on your thread rolling specification.